- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

End Mill Resharpening is a crucial process in tool maintenance that helps restore the cutting performance of worn or damaged end mills. By resharpening tools instead of replacing them, manufacturers can achieve significant cost savings while also extending the lifespan of their cutting tools. This process not only reduces the need for frequent tool replacements but also ensures consistent performance, which is vital for high-precision machining operations. The resharpening process involves carefully grinding the worn edges of the end mill to restore its geometry, sharpness, and overall cutting efficiency. With the use of advanced resharpening machines and precise grinding techniques, the tool can be brought back to more than 95% of its original cutting performance, ensuring high-quality results and improving production efficiency. By focusing on precision and efficiency, end mill resharpening helps maintain the reliability and effectiveness of tools in a cost-effective manner.

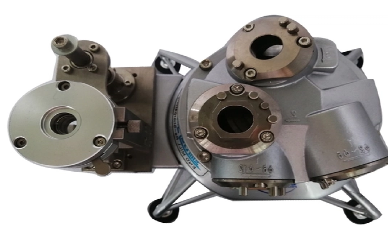

The End Mill Resharpening Machine is the core equipment required for restoring the cutting edges of end mills. It is designed to provide precise grinding of various tool geometries, including 2-edge, multi-edge, and coated tools. Key features include:

CNC control systems for precise adjustments of grinding parameters, such as grinding angle, tool rotation speed, and positioning.

High-precision clamping systems to securely hold tools in place during grinding, ensuring accurate sharpening.

Advanced grinding technology for restoring complex geometries, such as spiral grooves, peripheral edges, and end edges.

Automated or semi-automated functions that reduce human error and improve consistency in the grinding process.

The machine’s specifications may vary depending on the model, but it is important to choose one that fits the specific needs of the end mill types and sizes being sharpened.

Accurate measurement tools are essential for ensuring the precision of the resharpened tool. Micrometers, gauges, and calipers are used to measure:

Back angle: Ensuring the angle is within the desired tolerance for optimal cutting performance.

Tool diameter and edge sharpness: To verify that the grinding process has restored the tool to the correct size and sharpness.

Runout: Monitoring radial runout and end runout ensures the tool maintains precision and minimizes vibration during use.

These instruments allow for real-time checks during the resharpening process, ensuring that each tool meets exacting standards for quality and performance.

Safety is critical during the resharpening process due to the high-speed grinding and potential flying debris. Essential safety equipment includes:

Safety glasses to protect the eyes from dust, sparks, and particles generated during grinding.

Gloves to prevent hand injuries when handling sharp tools or machinery components.

Hearing protection (optional but recommended) to protect against the loud noise generated by grinding operations.

Protective clothing and aprons to shield against sparks and metal fragments.

Before beginning the resharpening process, it’s crucial to inspect the tool for visible signs of wear, damage, and irregularities. Look for dull edges, chipped cutting surfaces, or any visible cracks that may impact performance. It’s important to identify the type of end mill you're working with (such as 2-edge, 4-edge, or other multi-edge designs), as different types require different grinding angles and settings. This ensures that the sharpening process restores the tool to its optimal cutting condition.

Once the tool has been inspected, proceed to set up the resharpening machine. Start by calibrating the machine and configuring the correct grinding parameters based on the type of end mill being resharpened. These parameters may include settings for grinding speed, grinding angle, and tool positioning. Next, select the appropriate clamping system to securely hold the tool in place during the grinding process. Proper clamping ensures accurate alignment and prevents tool slippage, which could lead to uneven sharpening.

With the machine set up, it’s time to start the grinding process. Activate the machine and carefully monitor the grinding operation to ensure that the tool is being sharpened evenly and accurately. Keep a close eye on the tool during the process, checking for any signs of improper grinding. If necessary, make adjustments to the settings (e.g., grinding speed, back angle) to optimize the grinding process and ensure the tool is restored to its original cutting capabilities.

After grinding, inspect the tool for edge sharpness, back angle, and overall precision. Use measuring tools like micrometers or gauges to ensure the tool’s geometry matches the desired specifications. Check that the cutting edges are sharp and smooth, and that the tool’s performance has been restored to the necessary standards. This step ensures that the tool is fully ready for use and capable of performing at its best in machining operations.

Once the tool is resharpened and inspected, it’s important to clean both the tool and the machine. Remove any remaining grinding residue from the tool, as these particles could interfere with its performance in future operations. Similarly, clean the machine to prevent debris buildup, which could affect its efficiency in future use. Finally, ensure the tool is free of any debris before storing or using it in the machining process.

To prevent premature wear and extend the lifespan of your end mills, regular cleaning and proper storage are essential. After each use, clean your end mills thoroughly to remove any debris, chips, or coolant residue that may accumulate on the tool. Use a soft brush or air gun to remove particles and keep the tool free from contaminants that can cause wear.

For storage, ensure that the end mills are stored in a dry, clean environment where they won’t come into contact with moisture or corrosive materials. Using tool holders or dedicated storage racks will help maintain the integrity of the cutting edges, preventing accidental damage or dulling.

To avoid excessive tool damage, adhere to best practices in tool handling and machining operations:

Use proper cutting parameters: Always use the right cutting speed, feed rate, and depth of cut to avoid overloading the tool, which can cause wear or breakage.

Use the right tool for the job: Ensure you’re using the correct type of end mill for the specific material and operation to avoid unnecessary strain.

Proper lubrication and cooling: Keep the tool properly lubricated and use coolant to reduce heat buildup, which can cause the tool to soften and wear faster.

Avoid impacts: Handle the tools carefully to avoid any physical impact or drop that could chip or damage the cutting edges.

Keep a close eye on the cutting performance of your end mills during operations. If you start to notice signs such as reduced cutting efficiency, increased surface roughness, or higher tool wear, it may be time for resharpening. Regular monitoring of tool performance helps prevent further damage and ensures that tools are resharpened before they lose their effectiveness completely. Knowing when to resharpen your tools will save you both time and money by optimizing tool life and minimizing downtime.

Most End Mill Resharpening Machines can handle 2-edge, multi-edge, and coated tools, but there may be limitations depending on the machine. Some machines may struggle with larger-diameter or specialized tools. Coated tools need careful handling to avoid damaging the coating. Always check the machine’s specifications for compatibility.

Signs your end mill needs resharpening include:

Dullness: Poor surface finish or difficulty cutting.

Reduced performance: Longer cutting times or less precision.

Visible damage: Chips, cracks, or worn edges.

Excessive heat: Tool overheating during use.

Regular tool inspection after each operation will help determine when it’s time to resharpen.

Common challenges include:

Incorrect alignment: Ensure the tool is properly aligned and clamped to avoid uneven grinding.

Machine calibration issues: Regular calibration checks are necessary for accuracy.

Uneven wear: Adjust the machine to accommodate specific wear patterns and ensure proper grinding angles.

Maintaining the machine and monitoring the process helps minimize these issues.

To restore cutting performance:

Measure precisely: Use micrometers and gauges to check tool dimensions.

Ensure proper alignment: Secure the tool correctly to prevent uneven grinding.

Set accurate grinding parameters: Optimize the machine settings based on the tool type and geometry.

These steps help achieve optimal performance after resharpening.

In conclusion, End Mill Resharpening is a valuable process for maintaining tool performance, reducing costs, and extending the lifespan of end mills. By regularly inspecting tools, setting up the machine correctly, and following a precise grinding process, you can restore tools to their original cutting efficiency. Key factors such as accurate alignment, proper machine calibration, and monitoring cutting performance during resharpening are crucial to ensuring optimal results. With proper care and attention, resharpened end mills can continue to perform at a high level, saving both time and money. Regular maintenance and careful monitoring of tool wear will help maximize tool longevity and machining efficiency, ultimately improving your overall productivity.