- All

- Product Name

- Product Keyword

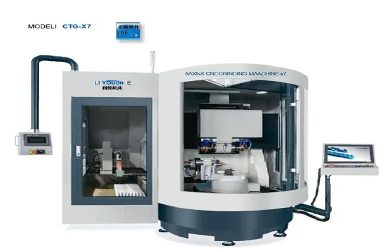

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 2025-11-19 Origin: Site

CNC tool grinding is a key process in tool manufacturing, ensuring that cutting tools like drills, end mills, and taps maintain their precision and sharpness for high-quality production. As industries demand more complex and accurate tools, CNC grinding technology has evolved to meet these needs, offering improved efficiency and precision.

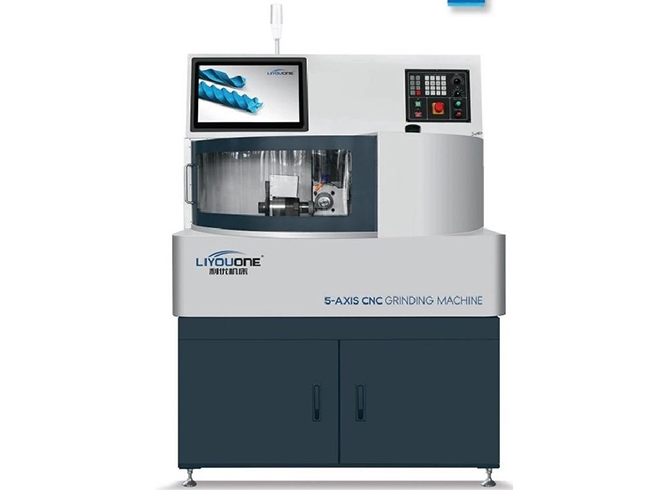

5-axis CNC tool grinding is an advanced method that adds two additional rotational axes to traditional 3-axis grinding. While 3-axis machines move along X, Y, and Z axes, 5-axis machines can approach the workpiece from multiple angles, enabling the creation of more intricate shapes and geometries in a single setup. This results in higher precision, faster processing times, and greater flexibility.

For manufacturers, understanding the differences between 5-axis and other grinding methods is crucial. While 3-axis grinders work well for simpler tasks, 5-axis machines excel in handling complex designs, reducing setup time, and improving efficiency. They are perfect for both mass production and custom, small-batch runs. With 5-axis CNC grinding, manufacturers can enhance precision, speed, and versatility in their operations.

A 5-axis CNC tool grinder is an advanced machine that can grind complex tool shapes with greater precision. Unlike traditional 3-axis or 4-axis machines, it features two additional rotational axes that provide enhanced flexibility for grinding intricate geometries in a single setup.

3-Axis Machines: Operate along X, Y, and Z axes, suited for simpler shapes, but require multiple setups for complex geometries.

4-Axis Machines: Add one rotational axis (A-axis) for better angle control but still have limitations in grinding complex or asymmetrical shapes.

5-Axis Machines: Incorporate two additional rotational axes (B and C axes), allowing for multi-directional grinding in a single operation, reducing setup time and improving precision.

The extra axes in 5-axis grinders enable:

Multi-directional grinding: Approach tools from different angles in a single setup, reducing repositioning.

Higher precision: Achieve more accurate shapes, especially for irregular or asymmetrical tools.

Better tool clearance: Adjust angles to avoid interference, improving surface finishes.

Precision: Fewer setup errors lead to highly accurate tools.

Speed: Reduced cycle times and fewer setups increase production efficiency.

Versatility: Ideal for industries requiring custom, complex tooling, such as aerospace and automotive.

Cost Efficiency: Less material waste due to precise grinding.

Tool Manufacturing: Creates precise cutting tools like drills and end mills.

Mold Making: Produces complex molds for plastic and metal casting.

Automotive and Aerospace: Grinds critical, high-performance components with tight tolerances.

5-axis CNC grinding allows for the grinding of complex geometries in a single setup, eliminating the need for multiple repositioning. This results in higher accuracy and reduces the risk of misalignment.

Multi-directional Grinding: The added axes provide flexibility to access various angles, making it ideal for intricate shapes.

Fewer Setups: Unlike traditional methods that need several setups, 5-axis machines streamline the process into one step, saving time and reducing error.

Traditional methods often require tool changes and machine repositioning, increasing setup time and downtime. 5-axis grinders minimize these steps.

Fewer Tool Changes: Multiple facets are ground in one cycle, reducing the need for frequent tool swaps.

Improved Setup Efficiency: With fewer machine adjustments, setup time is drastically reduced, leading to quicker production cycles.

5-axis machines offer greater precision and flexibility than traditional 3-axis machines. Their ability to grind at different angles ensures more accurate results.

Tighter Tolerances: 5-axis machines achieve high precision, critical for industries like aerospace or medical tooling.

Versatility: The ability to grind a wide range of tools and complex features makes these machines highly versatile for different manufacturing needs.

The precision and efficiency of 5-axis CNC grinders directly improve the quality of the finished product.

Improved Surface Finish: Multi-directional grinding reduces surface imperfections and enhances the tool’s finish.

Consistency: Automated grinding ensures consistent quality across all parts, meeting high standards required in precision industries.

For industries demanding precision, like aerospace and automotive, 5-axis CNC grinding provides the accuracy and efficiency needed for high-quality tooling.

Aerospace: Complex, tight-tolerance components can be ground accurately in a single setup.

Automotive: 5-axis grinders improve the precision and consistency of critical engine components.

Mold Making: Mold manufacturers benefit from the ability to create detailed, high-precision molds with reduced cycle times.

CNC tool grinders differ in the number of axes they use, which affects their movement and grinding capabilities.

3-Axis Machines: These work along three basic axes (X, Y, Z). They’re limited in their ability to reach all angles, making them suitable for simpler geometries but not for complex shapes.

4-Axis Machines: In addition to the three axes, 4-axis grinders have a rotating axis (A-axis), allowing the part to rotate during grinding. This enables more complex shapes but still requires multiple setups for certain features.

5-Axis Machines: These machines have full multi-directional movement with the addition of two more axes (A and B), allowing for complex shapes and undercuts to be ground in a single setup.

5-axis machines offer significant improvements in both flexibility and accuracy.

Flexibility: They can handle more complex geometries, such as undercuts or curved surfaces, which 3-axis and 4-axis machines can’t achieve in a single pass.

Accuracy: 5-axis machines reduce setup errors, as they can approach the part from multiple angles in one go, ensuring better precision, especially for tight tolerances.

Mold Making: 5-axis grinders excel in creating intricate molds with undercuts and complex features, reducing setup time and errors compared to 3-axis and 4-axis machines.

Aerospace Parts: With complex shapes and tight tolerances, aerospace components like turbine blades require 5-axis grinding for high precision and material integrity.

Automotive Components: Automotive parts, such as engine gears or valve seats, benefit from 5-axis grinding for tight tolerances and intricate designs.

Medical Devices: 5-axis grinders are ideal for manufacturing precision tools or implants with complex curves, ensuring accuracy and surface finish.

5-axis CNC tool grinding machines improve production efficiency, reduce costs, and enhance overall quality. Their ability to perform multiple tasks in one setup significantly impacts manufacturing processes, especially in high-precision industries.

5-axis machines reduce downtime by completing complex grinding tasks in a single setup, minimizing tool changes and manual interventions. Automated cycles and optimized programming allow for longer, uninterrupted runs, increasing overall output. Operators can load parts and let the machines run without constant supervision, improving machine utilization.

The efficiency of 5-axis grinders leads to substantial cost savings. Fewer tool changes and quicker setups reduce labor costs. Precision grinding also minimizes material waste by ensuring parts are made correctly on the first pass, which cuts down on rework, scrap, and tooling costs.

5-axis CNC grinders offer a competitive edge in industries requiring complex geometries and tight tolerances, such as aerospace, automotive, and medical devices. These machines reduce production times and ensure high-precision parts, improving both speed and quality.

Aerospace: Precision parts like turbine blades and engine components are made efficiently with 5-axis grinders.

Automotive: Complex parts and finishes are produced faster, meeting tight specifications.

Medical Devices: High-precision tools and implants are created with fewer defects and reduced rework.

5-axis grinding allows multi-angle approaches, ensuring greater precision and finer finishes without repositioning, unlike traditional methods that may introduce inaccuracies.

It reduces tool changes and repositioning by completing complex tasks in one setup, resulting in faster cycle times and higher throughput.

Aerospace, automotive, and mold making industries benefit most due to the high precision and flexibility needed for complex parts.

Yes, it is ideal for small-batch production due to quick reconfiguration and minimal setup, making it efficient for diverse tool requirements.

5-axis CNC tool grinding represents a significant leap in precision, efficiency, and versatility over traditional grinding methods. Its ability to handle complex geometries in a single setup not only improves the quality of finished products but also enhances production speed, reducing downtime and tool changes. Industries requiring high precision, such as aerospace, automotive, and mold making, benefit most from these capabilities. Additionally, the flexibility of 5-axis grinders makes them well-suited for both large-scale and small-batch production runs. By incorporating 5-axis CNC grinding, manufacturers can achieve higher precision, reduced costs, and improved overall efficiency, positioning themselves ahead in a competitive market.