- All

- Product Name

- Product Keyword

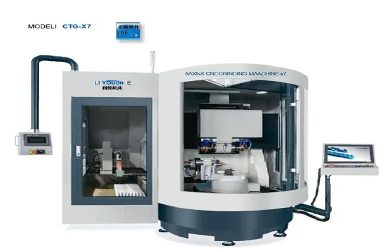

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

CNC tool grinding machines are essential in modern manufacturing, providing high precision and repeatability for producing cutting tools. These machines automate the grinding process, enabling manufacturers to achieve accurate and complex geometries that are difficult to obtain with manual methods. In industries like aerospace, automotive, and mold making, complex tool shapes and precise angles are critical for performance and quality.

Achieving these complex geometries is vital for manufacturing intricate components, such as turbine blades or custom molds. CNC tool grinding machines excel in this area by using multi-axis capabilities to grind tools from multiple angles in a single setup, ensuring tight tolerances and reducing errors. This efficiency not only improves product quality but also reduces setup times, making CNC tool grinding indispensable for high-precision tool production.

CNC (Computer Numerical Control) technology controls machine tools like grinders, allowing precise and automated shaping of cutting tools. CNC

tool grinding machines use rotating abrasive wheels to sharpen and shape tools with high precision. Through computer programming, these machines eliminate manual intervention and ensure consistent, accurate results.

CNC tool grinders use computer programs to direct the movements of the grinding wheel and tool holder. The machine operates along multiple axes (typically three to five), allowing it to grind tools from various angles. Advanced CNC grinders can create complex shapes and sharp edges by controlling parameters like feed rate, wheel speed, and angle.

CNC grinders ensure precise, repeatable results by following programmed instructions. Unlike manual grinding, which is subject to human error, CNC machines produce identical tools every time, making them ideal for industries requiring tight tolerances, such as aerospace and automotive. The automation reduces variability, improves consistency, and minimizes material waste, ensuring high-quality results with minimal labor.

Complex geometries refer to tools with intricate shapes, such as multi-faceted edges, tapered surfaces, or curved profiles, that are essential for precise performance. These geometries require advanced grinding techniques, as they often involve multiple angles, detailed contours, and compound curves. CNC tool grinding machines can precisely control the grinding process to achieve these complex shapes, ensuring high performance and durability.

Several industries rely on tools with complex geometries:

Aerospace: Aerospace parts like turbine blades and landing gear need tools with precise geometries to meet strict tolerances.

Automotive: Automotive tooling for engine parts and precision gears often requires intricate shapes to ensure smooth performance.

Mold Making: Tools for mold making, such as those for injection molds, require complex contours to produce high-quality parts.

Grinding complex geometries manually or using traditional methods presents challenges:

Precision Issues: Manual grinding depends on the operator's skill, which can lead to inconsistencies and errors, affecting tool performance.

Time-Consuming: Achieving intricate shapes manually requires multiple setups, increasing production time and labor costs.

Limited Flexibility: Traditional machines may not support the multi-axis movements needed for complex geometries, making them unsuitable for fast production or custom tooling.

Risk of Tool Damage: Manual methods can damage the tool due to human error or improper technique, resulting in uneven surfaces or wear on the tool.

CNC tool grinding machines solve these problems by offering high precision, automation, and flexibility, allowing for the efficient and accurate production of complex tool geometries.

CNC tool grinding machines, especially those with multi-axis capabilities (3-axis, 4-axis, 5-axis), are key to producing tools with complex geometries. Unlike traditional grinders, multi-axis machines can grind tools from various angles, allowing them to tackle intricate shapes like multi-faceted edges, tapered surfaces, and curved profiles with high precision.

The extra axes in CNC grinders increase both flexibility and accuracy during the grinding process:

3-Axis Machines: These machines grind along three linear axes (X, Y, Z), which is ideal for simpler tool shapes but limited in handling more complex geometries.

4-Axis and 5-Axis Machines: These machines introduce additional axes (A and B), allowing the grinding wheel to move in more complex patterns. This multi-directional motion enables the creation of highly intricate shapes, such as tools with irregular or curved surfaces, with greater precision than 3-axis machines.

The additional axes enable the grinding wheel to approach the tool from various angles simultaneously, increasing the precision and flexibility of the grinding process.

A significant advantage of multi-axis CNC grinding is the ability to grind from multiple angles without repositioning the tool. This eliminates the errors that often occur during manual repositioning and ensures that the geometry is accurately replicated throughout the process. For example, when grinding a tapered tool or a tool with multiple facets, a 5-axis machine can adjust in real-time, saving time and reducing the need for manual intervention.

CNC grinding machines are powered by advanced software that ensures the accuracy of complex geometries. These systems use algorithms to control the grinding wheel’s movement, optimizing cutting depths, angles, and speeds. The software also provides real-time feedback, adjusts parameters automatically, and can simulate the grinding process to prevent errors before cutting begins.

By integrating design data from CAD systems, CNC grinders can directly translate digital designs into grinding instructions, ensuring high-precision results and reducing the chance of errors.

CNC grinders can adapt to various materials, such as carbide, high-speed steel, and cobalt, automatically adjusting settings to match the material’s properties. This flexibility ensures consistent precision, even when working with different materials and tool types. Whether grinding drills, end mills, or custom tools, CNC grinders maintain accuracy in complex geometries, making them indispensable for industries that require versatile and high-precision tooling.

CNC tool grinding machines deliver high precision by automating the process, minimizing human error and ensuring consistent results across large production runs. The ability to grind from multiple angles without repositioning ensures that complex shapes are replicated accurately every time.

CNC grinders extend tool life by providing precise grinding that minimizes uneven wear. This reduces the need for frequent re-grinding, allowing tools to maintain peak performance for longer periods, which is crucial in high-precision industries.

Multi-axis CNC grinders improve time efficiency by cutting down on tool changes and machine reconfigurations. By completing multiple steps in one setup, these machines reduce downtime, leading to faster cycle times and higher throughput, which benefits both high-volume and custom production.

CNC tool grinders offer exceptional flexibility, easily adapting to a variety of geometries and production needs. They are ideal for producing both complex, custom tools and small-batch runs, making them perfect for industries like aerospace, automotive, and mold making. Their versatility reduces the need for multiple machines and manual setups, streamlining operations.

Operating CNC tool grinding machines, especially for complex geometries, requires specialized training. Operators need to understand machine capabilities, programming, and grinding parameters. Without this knowledge, there’s a risk of underusing the machine’s potential or producing inconsistent results.

Accurate machine calibration is essential for achieving precise geometries. Regular calibration ensures correct alignment and grinding wheel positioning. Misalignment can lead to dimensional errors, affecting tool performance. This is particularly crucial for complex shapes, where small deviations can cause significant issues.

Different materials, like carbide or high-speed steel, require specific grinding approaches. Harder materials need adjustments in wheel speed, feed rate, and cooling methods to maintain precision. These materials are harder to grind, requiring robust equipment to ensure quality and efficiency during the grinding process.

Multi-axis CNC grinders allow tools to be ground from various anglesin a single setup, ensuring precision and accuracy when creating intricate and complex shapes.

Yes, CNC tool grinding machines are highly versatile and can be programmed to handle various materials, including metals, ceramics, and composites, while maintaining precision in complex geometries.

CNC machines operate based on computer-controlled programs that follow precise calculations, reducing the chances of human error compared to traditional manual grinding methods.

Yes, CNC grinders are well-suited for both small and large batch production, making them ideal for custom tool manufacturing with complex geometries, reducing setup times and ensuring consistency.

CNC tool grinding machines have revolutionized the way manufacturers create highly accurate and complex tool geometries. With their multi-axis capabilities, these machines offer unmatched precision, enabling the production of intricate tool shapes that would be difficult or impossible to achieve with traditional methods. As industries like aerospace, automotive, and mold making demand higher levels of precision and efficiency, CNC grinding technology has become a crucial tool for maintaining competitiveness.

The impact of CNC grinding on these sectors is profound, providing not only better quality tools but also faster production times and more consistent results. Manufacturers who invest in CNC tool grinding machines gain the flexibility to meet diverse production needs while ensuring high-quality outcomes. By embracing CNC technology, businesses can significantly enhance their operational efficiency, reduce waste, and secure a competitive edge in the marketplace.