- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

In the modern manufacturing landscape, efficiency and precision are paramount. Industrial drill sharpening machines have emerged as critical tools that ensure drills maintain their optimal cutting performance, directly impacting product quality and operational productivity. As industries strive for excellence, understanding the various Types of Industrial Drill Sharpening Machines becomes essential. This comprehensive guide delves into the features and benefits of these machines, exploring how they serve as indispensable assets across multiple sectors.

Industrial drill sharpening machines are specialized equipment designed to recondition drill bits, restoring them to their original sharpness and geometry. By maintaining the precise angles and cutting edges, these machines enhance drilling efficiency, extend tool life, and reduce downtime. The technology behind these machines has evolved significantly, incorporating advanced features that cater to a wide range of drilling tools and applications.

In manufacturing settings, drill bits are subject to wear and tear due to continuous use on various materials. Dull or improperly sharpened drills can lead to poor-quality holes, increased power consumption, and higher chances of tool breakage. Implementing industrial drill sharpening machines mitigates these issues by ensuring consistent drill performance. According to a study by the Manufacturing Engineering Journal, companies that utilize sharpening machines experience a 25% increase in tool lifespan and a 15% reduction in production costs.

There is a diverse array of drill sharpening machines available, each tailored to specific needs and drill types. The selection of the appropriate machine depends on factors such as drill size, material, and the complexity of the drill geometry.

Manual machines are the most basic type, requiring operator skill to achieve the desired drill point geometry. They are cost-effective for small workshops where precision demands are moderate. However, the reliance on manual operation can lead to inconsistencies, making them less suitable for high-precision applications.

Automatic machines utilize programmed settings to sharpen drills with minimal operator intervention. These machines offer greater consistency and are ideal for high-volume environments. They can handle a range of drill sizes and types, enhancing productivity and ensuring uniform quality across all sharpened tools.

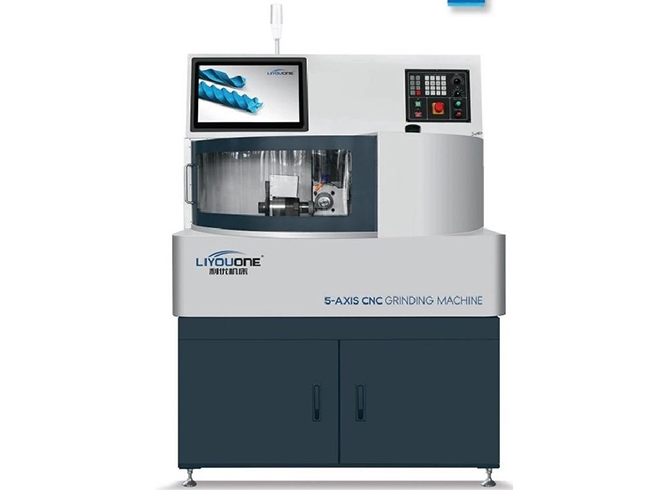

Computer Numerical Control (CNC) machines represent the pinnacle of precision in drill sharpening technology. They are capable of complex geometries and can handle specialty drills used in advanced manufacturing sectors. CNC machines provide unparalleled accuracy and repeatability, making them indispensable in industries where precision is non-negotiable.

For specialized applications, standard machines may not suffice. In such cases, a custom Industrial Drill Sharpening Machine is the solution. These machines are tailored to meet specific operational requirements, accommodating unique drill designs and materials.

Customization allows for the integration of specialized features such as advanced coolant systems, unique grinding wheel configurations, and automation capabilities. This ensures that the machine aligns perfectly with production demands, enhances efficiency, and provides a competitive edge in the market.

A leading aerospace manufacturer required a sharpening machine capable of handling superalloy drills with complex geometries. By investing in a custom machine, they achieved a 30% increase in sharpening efficiency and a significant reduction in tool replacement costs. This illustrates the tangible benefits of customization in high-stakes industries.

Different industries have unique requirements that necessitate specialized drill sharpening solutions. The adaptability of these machines makes them valuable assets across diverse sectors.

In the medical field, precision is paramount. Surgical instruments, especially drills used in orthopedic procedures, must meet stringent standards. An Industrial Drill Sharpening Machine for Medical industry ensures that these tools maintain their sharpness and precision, which is critical for patient safety and surgical success. The use of CNC sharpening machines in this sector has been linked to improved surgical outcomes and reduced procedural times.

The aerospace industry deals with advanced materials like titanium and composites, requiring drills that can withstand extreme conditions. Utilizing an Industrial Drill Sharpening Machine for Aerospace applications ensures tools are sharpened to handle these materials effectively. High-precision sharpening reduces the risk of drill failure and contributes to the overall safety and performance of aerospace components.

Mold manufacturing demands high levels of accuracy to produce components with tight tolerances. An Industrial Drill Sharpening Machine for Mold Manufacturing ensures that drills used in cavity creation are consistently sharpened to exact specifications. This precision translates to higher quality molds and reduces material wastage due to errors.

The effectiveness of a drill sharpening machine is determined by its features. Modern machines come equipped with advanced technologies that enhance functionality and user convenience.

Precision is achieved through high-quality grinding wheels and sophisticated alignment systems. Machines are capable of restoring the drill’s original geometry with minimal material removal, preserving the integrity of the tool. Precision grinding ensures that the drill performs as intended, maintaining hole accuracy and surface finish.

Automation reduces the reliance on operator expertise and increases repeatability. Machines with programmable controls allow for quick setup and changeovers between different drill types and sizes. This flexibility is essential in dynamic production environments where responsiveness is key.

Modern machines feature intuitive interfaces that simplify operation. Touchscreen displays and guided menus enable operators to perform complex sharpening tasks with ease. This reduces training time and minimizes the potential for user error.

Investing in drill sharpening equipment yields numerous benefits that positively impact manufacturing operations.

Sharpening drills extends their usable life, reducing the frequency of purchasing new tools. Over time, this leads to significant cost savings. An analysis by Industrial Tooling Magazine indicates that companies can save up to 50% on tooling costs by incorporating sharpening machines into their maintenance routines.

Sharp drills improve cutting efficiency, resulting in faster drilling times and improved workflow. This productivity boost can lead to increased output and the ability to meet tighter production schedules.

Consistently sharpened drills produce more accurate holes with better surface finishes. This quality improvement is critical in applications where precision affects the performance of the final product.

Integrating sharpening machines requires careful consideration to maximize their benefits. Factors such as machine selection, training, and maintenance play crucial roles.

Assess your operational needs to determine the best machine type. For complex and high-precision requirements, CNC machines are advisable. For less demanding applications, automatic or manual machines may suffice. Consulting with manufacturers can provide insights into the best options for your specific situation.

Proper training ensures that operators utilize the machines effectively. Training programs should cover machine operation, safety protocols, and maintenance procedures. Skilled operators can optimize machine performance and extend its lifespan.

Regular maintenance is essential to keep machines running efficiently. This includes routine inspections, replacing worn components, and software updates for CNC machines. A well-maintained machine delivers consistent sharpening quality and reduces unexpected downtime.

The drill sharpening industry continues to evolve with technological advancements aiming to enhance efficiency and precision.

AI integration enables machines to learn from sharpening processes, optimizing settings for different drills automatically. This technology reduces human error and further enhances consistency in tool maintenance.

The development of new grinding wheel materials and coatings extends the capabilities of sharpening machines. These advancements allow machines to handle harder drill materials and complex geometries more effectively.

Remote monitoring systems enable real-time diagnostics and performance tracking. Users can receive alerts for maintenance needs and troubleshoot issues promptly, minimizing downtime and enhancing productivity.

Industrial drill sharpening machines are vital components in modern manufacturing, offering significant benefits in cost savings, productivity, and quality. By selecting the appropriate machine type and ensuring proper integration into operations, companies can realize substantial improvements. Embracing technological advancements and customization options, such as those found in a custom Industrial Drill Sharpening Machine, positions businesses at the forefront of efficiency and innovation. As industries continue to evolve, the role of drill sharpening machines will undoubtedly become even more integral to achieving manufacturing excellence.